At Master Engineering, we offer comprehensive services tailored to assist businesses within the wastewater treatment industry in cutting costs and optimizing efficiency. Drawing upon our expertise in designing and constructing advanced wastewater treatment systems, we provide customized solutions to address your specific requirements and enhance operational performance. Our cutting-edge systems incorporate state-of-the-art technologies, including membrane bioreactors, advanced oxidation processes, and intelligent control systems, resulting in reduced energy consumption and chemical usage while elevating overall treatment efficacy.

Our end-to-end services encompass feasibility studies, system design, equipment fabrication, installation, and ongoing maintenance, ensuring a seamless integration process and long-term reliability. You can trust us to deliver cost-effective and efficient wastewater treatment solutions aligned with your business objectives and regulatory mandates. Our solutions enable you to achieve sustainable operations while maintaining rigorous environmental compliance.

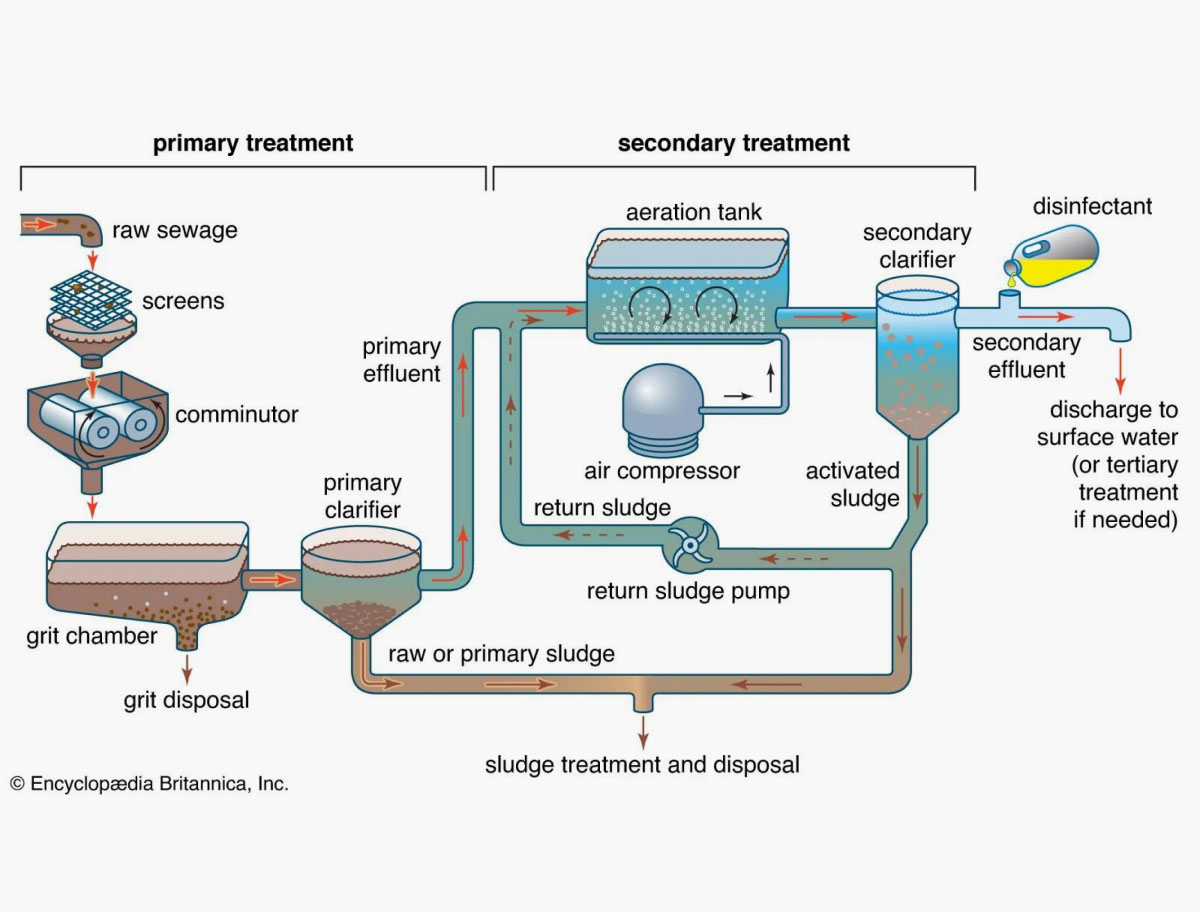

For the creation of wastewater treatment systems, Master Engineering conducts thorough feasibility studies to assess the unique requirements of your wastewater treatment needs. We consider factors such as wastewater volume, characteristics, and regulatory obligations. This analysis forms the basis for a personalized wastewater treatment system design, including process flow diagrams, equipment selection, and sizing of essential components such as pumps, mixers, tanks, screens, filters, and disinfection units.

Master Engineering oversees the installation and integration of equipment, ensuring precise alignment, calibration, and functionality. Collaborating closely with construction and installation teams, we ensure the smooth incorporation of the treatment system into your designated facility. Additionally, we offer ongoing maintenance services to ensure the efficient and reliable operation of your wastewater treatment system.

We incorporate advanced treatment technologies, including activated carbon filters, membrane bioreactors (MBRs), or advanced oxidation processes (AOPs), to achieve heightened treatment levels and eliminate additional contaminants. Moreover, a comprehensive monitoring and control system is implemented to continuously oversee key parameters such as flow rates, pH levels, and pollutant concentrations.

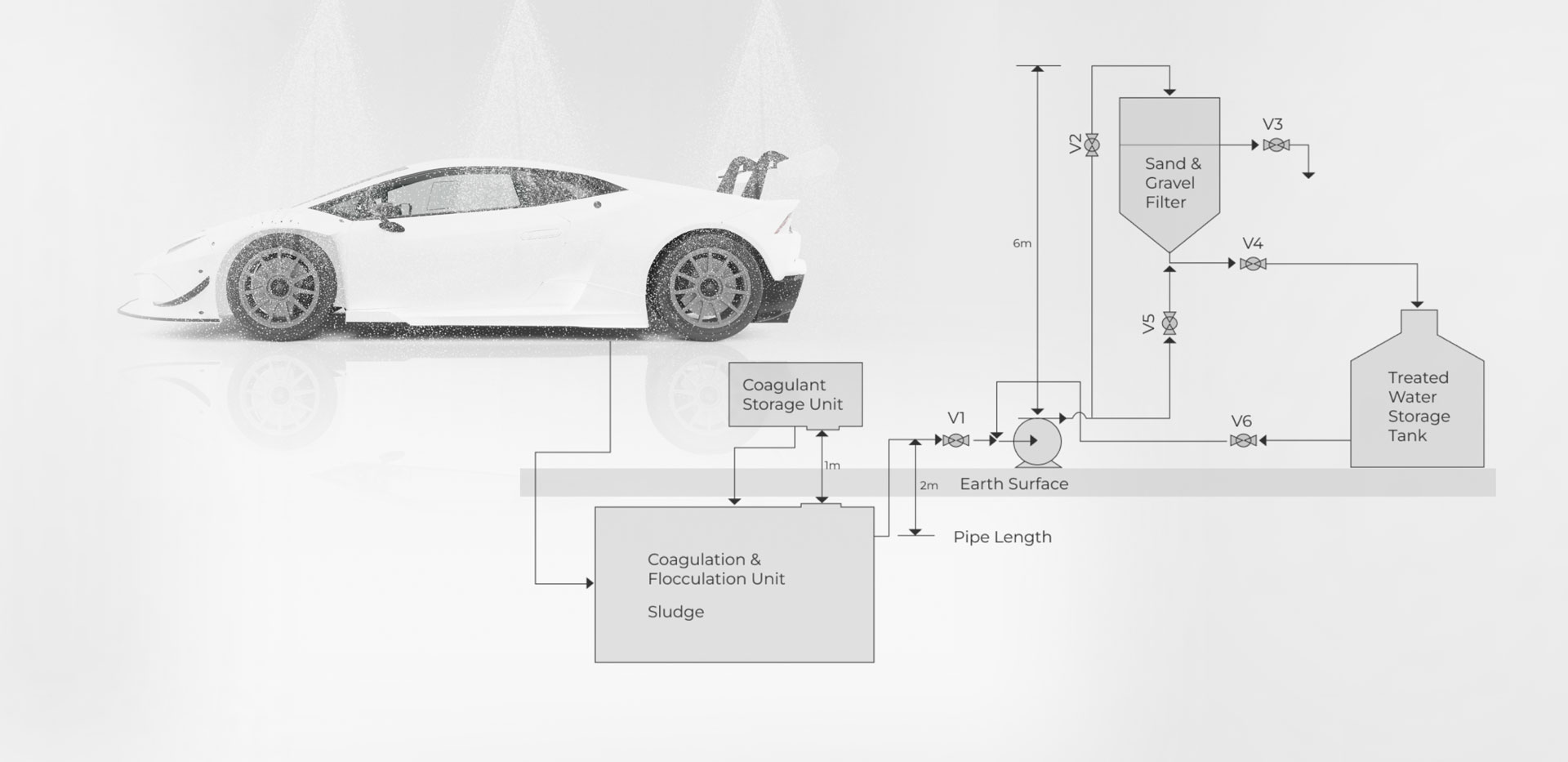

For car wash wastewater optimization, Master Engineering installs oil-water separators or grease traps to eliminate oils, greases, and solid contaminants from wastewater before it enters the treatment system. Sedimentation tanks or settling basins are employed to allow solids to settle out, thereby reducing the load on subsequent treatment processes. The use of filtration systems, such as sand filters or membrane systems, further removes suspended solids and contaminants, enabling the safe reuse of treated water.

Case Study

The City of Wetaskiwin, Alberta, embarked on a retrofitting project aimed at elevating the reliability, performance, and capacity of its aerated lagoon. This initiative was driven by the goal of meeting stringent provincial environmental standards. The pivotal change involved the replacement of the lagoon's coarse bubble aeration system with advanced fine bubble aeration technology. This transition resulted in significantly improved and more efficient wastewater treatment, concurrently leading to notable reductions in energy expenditures.

Furthermore, the excess sludge generated within the lagoon found a sustainable purpose as a nutrient source for neighboring agricultural land. By embracing more efficient blowers and an enhanced operating system, the city achieved remarkable reductions in operating costs. The enhanced technology and processes also contributed to decreased requirements for lagoon desludging, consequently leading to substantial reductions in maintenance expenses. This comprehensive approach not only aligns with environmental standards but also exemplifies cost-effective and sustainable wastewater management.3S

Case study: Energy-efficient upgrades reduce operating costs at Wetaskiwin wastewater treatment plant | Green Municipal Fund

350 Hwy 7 E # 307, Richmond Hill, ONL4B3N2,Canada

Monday – Friday 9am to 5pm