Master Engineering is your premier partner, providing a comprehensive array of metal smelting services meticulously tailored to your unique requirements. Backed by our profound expertise in metallurgy and cutting-edge smelting technologies, we present a diverse range of solutions aimed at optimizing metal extraction and refining processes.

Our extensive service portfolio encompasses:

With a commitment to innovation and advanced technologies, we orchestrate optimized metal recovery, heightened energy efficiency, and minimized environmental impact. From inception through continuous operational support, our dedicated approach ensures the delivery of cost-effective and sustainable metal smelting solutions. We align with your objectives, uphold regulatory compliance, and elevate the overall efficiency of your smelting operations.

Master Engineering specializes in designing and optimizing refining processes to achieve targeted metal purity levels, minimize impurities, and elevate yield and recovery rates. Our expertise encompasses the selection and installation of appropriate refining equipment, seamlessly integrating it into your refining process. Our engineering prowess extends to implementing heat recovery systems that harness and utilize refining-generated heat, thereby enhancing energy efficiency.

We prioritize environmental stewardship by crafting tailored emissions control systems, effectively mitigating the impact of refining process emissions on air quality. Our focus on optimization extends to material handling, where we enhance efficiency, diminish manual handling, and mitigate the risks of material contamination or loss during refining.

Master Engineering excels in elevating Ingot casting lines through meticulous analysis and optimization. By scrutinizing the ingot casting process, we unearth opportunities for enhancement. Parameters such as casting speed, mold design, cooling rates, and alloy compositions undergo evaluation. Optimization of these factors results in improved ingot quality, reduced casting defects, and heightened productivity. Recommendations for upgrades or replacements, such as modernizing mold technologies or implementing automated casting processes, are tailored to enhance performance and efficiency. The outcome is augmented casting yields, elevated product quality, and minimized downtime.

Our extensive experience includes the implementation of advanced quality control systems, facilitating real-time monitoring through automated inspection and statistical process control. Prompt identification of deviations enables swift corrective action, refining product consistency and reducing waste. We streamline material handling and logistics processes, optimizing ingot production flow. This entails efficient material feeding, mold preparation, ingot removal, and finished ingot handling, collectively minimizing bottlenecks, reducing cycle times, and boosting operational efficiency.

Master Engineering provides comprehensive training programs to empower casting line operators and technicians. Our programs encompass best practices, safety protocols, and equipment operation and maintenance, enhancing their skills and contributing to a safer and more efficient work environment.

Our comprehensive range of services are tailored to optimize the alloying process, encompassing alloy design and development, process optimization, quality control, and material testing. Leveraging advanced techniques like computational modeling, thermodynamic analysis, and metallurgical expertise, we refine alloy compositions and processing parameters to achieve optimal results. Specific enhancements we offer include:

We employ computational tools and expertise to analyze desired material properties, recommending optimal alloy compositions. Factors such as strength, corrosion resistance, heat resistance, and specific application requirements are considered.

Our experts evaluate existing alloying processes, identifying improvement opportunities. This involves refining melting and casting techniques, optimizing heat treatment cycles, and implementing controlled cooling methods for enhanced microstructural properties and mechanical performance.

Throughout the alloying process, we enforce rigorous quality control measures. This includes material testing, mechanical property analysis, non-destructive testing, and metallographic examination.

Master Engineering specializes in delivering turnkey extrusion systems, providing comprehensive services from design to construction and optimization. Our expertise in extrusion technology ensures fully integrated solutions covering material handling, die design, equipment selection, process control, and quality assurance. With a focus on efficiency, reliability, and product quality, our turnkey extrusion systems are designed to maximize productivity and minimize waste, adhering to industry standards.

Forward integration empowers you to take control over post-extraction and smelting activities, spanning from raw materials to finished products. Master Engineering assists you in maintaining quality control across the entire production process, ensuring products meet customer requirements and industry standards. This approach reduces reliance on volatile commodity markets and offers advantages like improved cost control, supply chain management, and responsiveness to market demands.

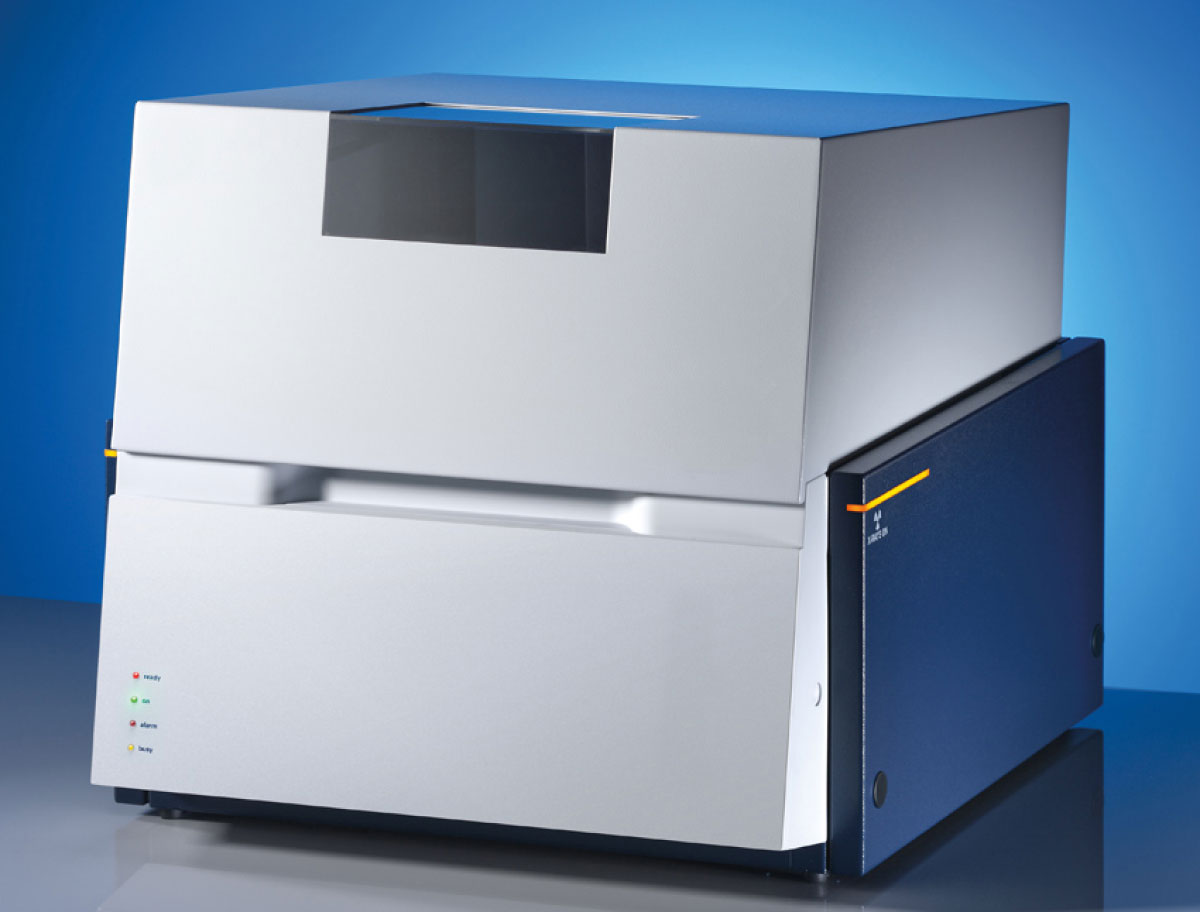

Master Engineering's metal refining solutions encompass designing and implementing processes and technologies for efficient metal purification. Automation integration enhances efficiency, accuracy, and consistency. By monitoring and regulating parameters through sensors, actuators, and control systems, we ensure reliable refining results. Data analysis identifies inefficiencies and optimizes parameters, contributing to superior refining outcomes.

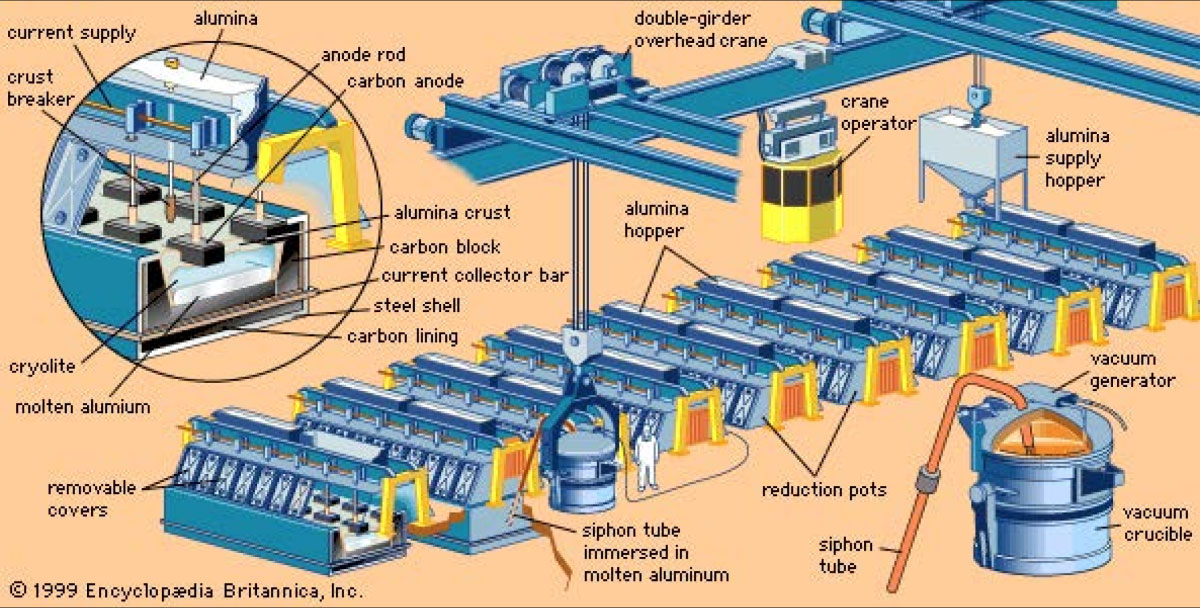

Integrating advanced analytical techniques into the metal refining system can offer real-time feedback and elevate process control. For instance, employing spectroscopic analysis or X-ray fluorescence (XRF) can rapidly determine the metal's composition and identify impurities.

The optimization of metal refining entails addressing waste management and environmental concerns. The implementation of efficient waste treatment systems, such as filtration, precipitation, or electrochemical methods, can minimize the release of pollutants into the environment.

Establishing a culture of continuous improvement is essential for optimizing metal refining. This objective can be achieved through consistent process evaluation, data analysis, and active employee engagement in the identification of enhancement opportunities. Cultivating an environment of innovation and knowledge sharing can stimulate efficiency gains, cost savings, and improved refining outcomes.

EY optimized an aluminum smelting operation for one of India’s largest integrated aluminum players.The company aimed to enhance energy efficiency without compromising quality or productivity, using analytics-driven methods to dynamically determine smelter operating parameters.

To address this challenge, EY developed a comprehensive cloud-based Digital Twin solution for the smelter operations. This solution had several key components:

EY's innovative approach led to significant improvements in energy efficiency and overall smelter performance, showcasing the power of analytics and technology in optimizing complex industrial processes.

Case Study: https://www.ey.com/en_in/mining-metals/how-artificial-intelligence-helped-an-indian-aluminum-major-reduce-energy-cost350 Hwy 7 E # 307, Richmond Hill, ONL4B3N2,Canada

Monday – Friday 9am to 5pm